Disclaimer

Peristaltic pump filling system FU4B-1 consists of 4 sets drive units, 304 stainless steel housing with good corrosion resistance.

Controller FC32S-1 and dispensing system FU4B-1 are separated, to allow flexible mounting way. Controller adopts 7-inch industrial touchscreen interface to operate easily and friendly, to control max 32channels.

Compatible pump heads are YZ1515x, YZII15, FG15-13, YZ2515x, YZII 25, FG25-13 and DMD 15-13.

Each channel has an independent membrane key and LED display, which can be used to set the channel address and calibrate the dispensing volume when the system is running or stops.

The pump could be controlled through controller, external control and RS485 communication, to meet the requirement from different user.

Each channel could be stopped filling without bottle.

CE certification.

| Parameters | FU4B-1&FC32S-1 |

| Filling volume | 0.1mL~9999.99ml |

| Filling accuracy | ≤±2% |

| Filling time | 0.5s~6000s |

| Filling cycles | 0~999999 (0 means unlimited)) |

| Number of channels | 4 |

| Display | 7-inch color LCD for parameters |

| Work mode | Parallel filling |

| Control mode | Touch screen control; Footswitch control; External control; Communication control |

| Calibration | Manual |

| Calibration method | Calibrate with volume or weight offline; Calibrate with ratio online |

| Parameter recipe | Can store 5 recipes |

| External control | start; disable channel |

| Communication control | Interface: RS485; Protocol: Modbus RTU |

| Dimensions (L x W x H) | 663x218x177mm |

| Power supply | FU2B-1-1: AC220±20%/150W; FC32S-1-2: AC90-260V/10W,50/60Hz |

| Operating temperature | 0℃-40℃ |

| Relative humidity | 20%-80% |

| IP rating | IP31 |

| Weight | 12kg |

Technical Specifications

FU2B-1 | FU4B-1 | FU5B-1 | |

Dispensing volume | 0.1ml-9999.99ml (resolution: 0.01ml) | ||

Dispensing time | 0.5s-6000s (resolution:0.1s) | ||

Interval time | 0.5s-999.9s | ||

Dispensing cycle | 0-999999, "0" means unlimited cycle | ||

Delay time before back suction | 0-60.0s | ||

Back suction angle | 0-1000° | ||

Channel quantity | 2 | 4 | 5 |

Display | LCD touchscreen control,external signal control or | ||

Start control signal input | Each dispensing unit has one pair of terminals for | ||

No bottle signal input | Each channel has individual terminals for the no | ||

Communication function | RS485 communication interface, Modbus protocol, | ||

Dispensing calibration | Dispensing volume of every channel can be calibrated | ||

Channel enable | Every channel can be set as enable or disable | ||

Fill/Backflow | All channels can be fast filling or backflowing at | ||

Channel address | Communication address of each channel can be set | ||

Password function | Protect the system parameters and prevent | ||

Dispensing parameter set | Dispensing parameters can be saved as a parameter | ||

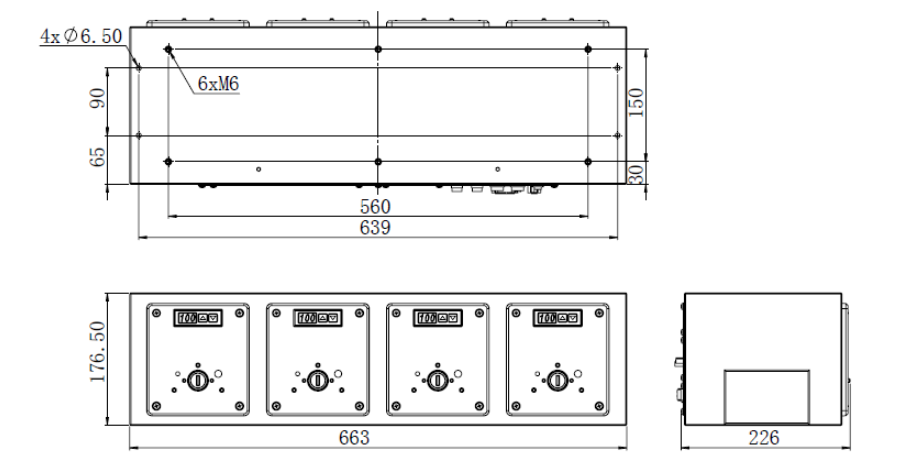

Dispensing unit | 343 x218x177mm | 663mm X218mm X177mm | 823mm X218mm X177mm |

Controller dimension(LXWXH) | 228 x60x146mm | ||

Power supply | FU2B-1/FU4B-1/FU5B-1:AC220V±20%/300W, | ||

Operating temperature | 0 to 40℃ | ||

Relative humidity | <80% | ||

IP rating | IP31 | ||

Weight | 6kg | 12kg | 15kg |

Contoller Weight | 1.7kg | ||

Compatible Pump Heads and Tubing

Model | Pump Head | Ref. Dispensing Volume (mL) | Tubing | Ref. Dispensing Time (s) | Precision | Dispensing ID (mm) | Productivity (pcs/min) |

FU2B-1 FC32S-1 | YZ1515x YZ II 15 FG15-13 | 0.3-0.5 | 13# | 1-1.2 | ≤±2% | ≤0.5 | 27-30 |

| 1.0-2.3 | 14# | ≤1.0 | |||||

| 2.6-5.1 | 19# | ≤1.5 | |||||

| 4.6-9.1 | 16# | ≤2.0 | |||||

| 10.0-19.0 | 25# | ≤3.0 | |||||

| 15.0-30.0 | 17# | ≤3.0 | |||||

| YZ2515x | 8.0-17.0 | 15# | ≤3.0 | ||||

| 12.0-24.0 | 24# | ≤3.0 | |||||

| YZ II 25 | 8.5-17.0 | 15# | ≤3.0 | ||||

| 15.0-24.0 | 24# | ≤3.0 | |||||

| 18.0-36.0 | 35# | ≤3.0 | |||||

| 25.0-48.0 | 36# | ≤3.0 | |||||

| FG25-13 | 9.0-17.0 | 15# | ≤3.0 | ||||

| 12.0-24.0 | 24# | ≤3.0 | |||||

| DMD15-13-B DMD15-13-D | 0.1-0.9 | 2x13# | ≤0.5 | ||||

| 0.2-2.3 | 2x14# | ≤1.0 | |||||

| 0.5-5.9 | 2x19# | ≤2.0 | |||||

| 2.0-10.0 | 2x16# | ≤3.0 | |||||

| 5.0-25.0 | 2x25# | ≤3.0 |

Dimension

Disclaimer

You are welcome to leave a message for consultation