Disclaimer

Mainly used in OEM equipment and instruments, especially for automation process of programmed task.

Rotary valve, panel installation, RS485/RS232/CAN bus communication control.

| Parameters | |

| Channel | 1 |

| Syringe size | 50uL、100uL、250uL、500uL、1mL、2.5mL、5mL、10mL、25mL |

| Accuracy | <=1.0 % (syringe ≥1 mL) |

| Precision | CV≤0.05% at full stroke (with syringe≥500uL) |

| Valve options | 3-port Y valve,3-port distribution valve,4-port valve,6-port distribution valve,9-port distribution valve,T valve,straight-through valve or distribution valve. |

| Wetted material | Borosilicate glasS,PTFE,PFA,CTFE,ETFE,UHMW-PE,Ceramic |

| Syringe fitting | 1/4"-28 thread |

| Max pressure | 0.68Mpa |

| Travel | 60mm |

| Time for full stroke | 1.26s-1200s |

| Full stroke | (standard mode):6000 steps,(microstep mode):48000steps |

| Resolution | 6000 steps with 0.01mm in 1 step;48000 microsteps with 1.25um in 1 microsteps |

| Communication interface | RS485,RS232,CAN bus |

| Protocol | Data terminal,OEM protocol(serial) or CAN |

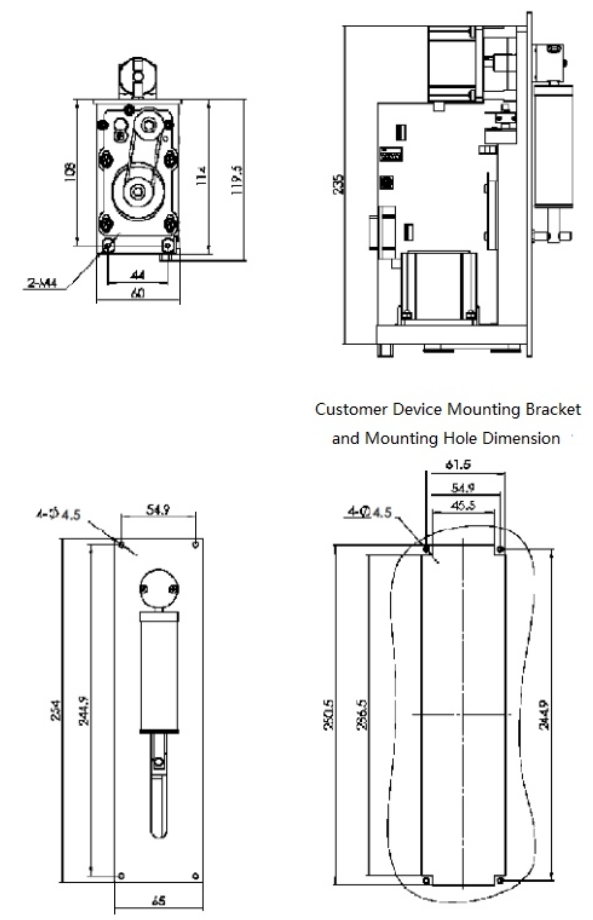

| Dimensions (L x W x H) | 114mm (L) x 65mm (W) x 254mm (H) |

| Power supply | DC 24V,1.5A(peak) |

| Operating temperature | 15℃~40℃ |

| Relative humidity | <80% RH,no condensation |

| Weight | 2.15 kg |

Technical Specifications

SP1-CX | MSP1-CX | |

Accuracy | ≤1.0 % (syringe ≥1mL) | |

Precision | CV≤0.05% at full stroke (with syringe ≥ 500uL) | CV≤0.05% at full stroke (with syringe ≥1mL) |

Wetted material | Borosilicate glass, PTFE, PFA, CTFE, ETFE, UHMW-PE,Ceramic | |

Dimension(L×W×H) | 114mm(L)x 65mm(W)x 254mm(H) | 110mm(L)x 44.4mm(W)x 127mm(H) |

Weight | 2.15kg | 1.0kg |

Power supply | DC 24V, 1.5A (peak) | |

Syringe fitting | 1/4″-28 thread | |

Syringe | 50uL, 100uL, 250uL, 500uL, 1mL, 2.5mL, 5mL, 10mL, 25mL | 50uL, 100uL, 250uL, 500uL, 1mL, 2.5mL, 5mL |

Syringe material | Borosilicate glass, stainless steel plunger with PTFE coating, PTFE or UHMW-PE plunger tip | |

Resolution (standard mode) | 6000 steps with 0.01mm in 1 step | 3000 steps with 0.01mm in 1 step |

Resolution (microstep mode) | 48000 microsteps with 1.25um in 1 microstep | 48000 microsteps with 0.625um in 1 microstep |

Travel | 60mm | 30mm |

Time for full stroke | 1.26s-1200s | |

Drive system | Ball screw drive with optical encoder | |

Turn Time | ≤250ms between adjacent ports | |

Valve options | 3-port Y valve, 3-port distribution valve, 4-port valve, 6-port distribution valve, 9-port distribution valve, T valve, straight-through valve or distribution valve. | |

Max pressure | 0.68Mpa | |

Fitting | 1/4″-28 thread | |

Interface | RS485, RS232, CAN bus, external control input and output | |

Protocol | Data terminal, OEM protocol (serial) or CAN | |

Baud rate | RS485 or RS232: 9600bps or 38400bps CAN bus: 100 KB, 125 KB 250 KB, 500 KB or 1MB | |

Format | Data bit: 8; parity: none; stop bit: 1; half duplex (RS232/485) | |

Topology group | Up to 15 pumps in one group, support group control and individually addressed | |

Upgrade firmware online | "One Click" by customer through PC Utility | |

Homing Algorithm | Plunger home position is identified by motor stall, which will reduce the dead volume of the system | |

Halt function | For better interactive control, "h" command is used to halt execution of the command string during plunger movement. To resume execution with "R" or "r" command | |

Microstep mode | Set microstep mode for smoother motion with 48000 microsteps per stroke, 1/8 microstepping or 1/16 microstepping | |

Programmable parameter | Programmable ramps, cut-off velocity, plunger speeds, backlash compensation, programmable work-flow command set , delays and loops, terminate moves, diagnostics, absolute and relative positions | |

Operating temperature | Recommended: 15℃-40℃ , use low temperature syringe for low temperature application | |

Operating Humidity | <80% RH, no condensation | |

Storage temperature | -20℃-65℃ | |

Storage Humidity | <80% RH, no condensation | |

Dimensions

Disclaimer

You are welcome to leave a message for consultation